M.A.S.DT kiln burner

The disc technology

The M.A.S.DT is the latest development in optimizing the burner’s efficiency. Placing the adjustable primary air openings directly at the burner tip leads to unobstructed injection of the air jets into the kiln.

M.A.S kiln burner

The Mono Airduct System

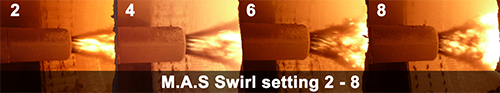

The patented M.A.S. rotary kiln burner offers essential advantages compared to conventional burner systems. The complete primary air flow is brought into an adjustable swirl with a minimum of losses.

The M.A.S. kiln burner was designed to set new standards in usability and efficiency with the highest effective momentum possible. The system is intended to offer maximum flame control and accuracy in flame setting. This is achieved by using only one single primary air channel which is directly guided into the required swirl.

Especially designed M.A.S. hoses, which can be manually or automatically adjusted, are used to set the swirl angle. This unique flame setting device offers a broader range of settings than any other system and guarantees a controllable and stable flame with any fuel combination. The high fuel flexibility and the remarkable burning results make the M.A.S. burner the most advanced kiln burner available.

Benefits:

- Highest fuel flexibility

- Significant decrease in electrical power consumption

- Simpler and more effective flame shaping

- Reproducible flame settings

- Easy burner maintenance

- Possibility to burn hard combustible fuels

Download our M.A.S. catalogue for further information.

Swirl gas burner SG

The swirl gas burner is an excellent example of an innovative modification of the M.A.S. burner design.

It is designed for 100% natural gas operation. The gas is split into the main gas (95 – 98%), which is fed through the flexible hoses instead of primary air. The flame shape is adjusted directly with the fuel and not with the primary air, which is a unique feature worldwide. Low-pressure air is used for cooling purposes only. This design allows maximum flame control with a minimum consumption of air.

The M.A.S./SG burner is also equipped with a ‘thermo-carbolysator’, which is built into the burners central gas channel and is fueled by approximately 2% - 5% of the total gas flow. A separate air supply is used to maintain the stoichiometric gas-to-air ratio. The thermo-carbolysator accelerates the process of the gaseous fuel heating until the gas is mixed with the secondary air. It provides continuous combustion without flame detachment during the heating up phase. Due to staged combustion the burner improves the burning of bright materials such as white cement and lime.

In the first combustion stage the thermo-carbolysator mixes natural gas with low-pressure air inside the burner, ignites it and forms a flame with the root located inside the burner. It provides an exceptionally stable satellite flame, since the ignition point is not inside the kiln area, but inside the burner.

In the second combustion stage the main gas flow is heated by the satellite flame to over 1000°C under the shortage of oxygen near the burner nozzles. At such conditions the main flame starts to glow, thus the thermal radiation affecting the clinker intensifies.

World Cement Article March 2018

Download |

Satellite burner

Maximize your solid secondary fuel input with our satellite burner technology.

To optimize the combustion of solid secondary fuels in the rotary kiln, following preconditions have to fulfilled:

- Injection in a zone with high temperature and high oxygen content

- Sufficient residence time

- Advanced control of combustion process

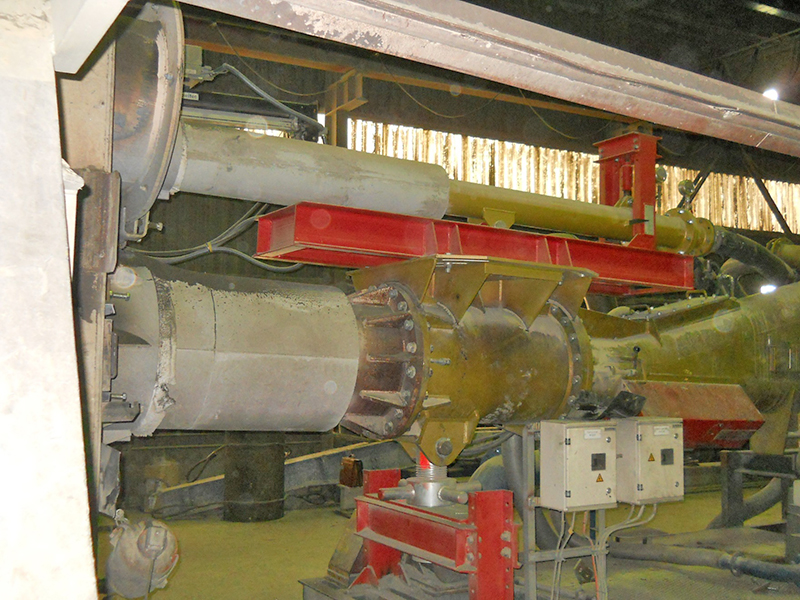

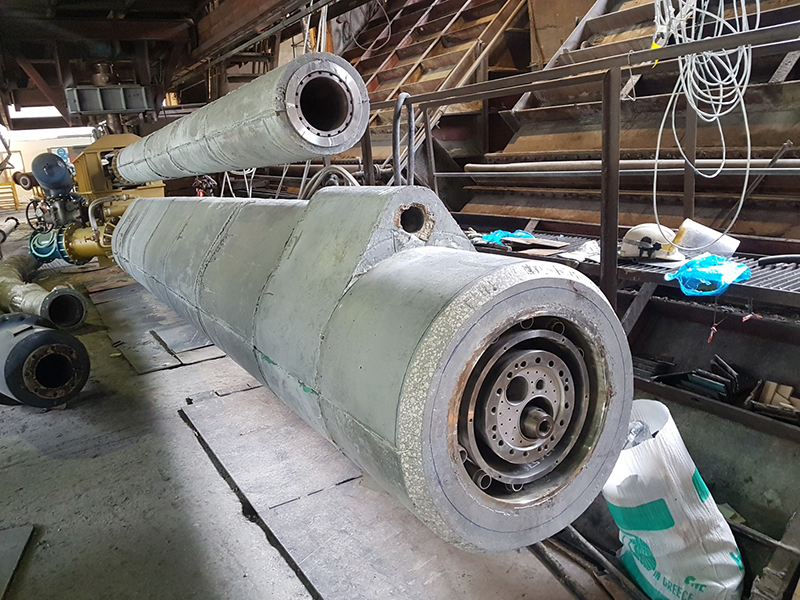

All these requirements can be met with the installation of a Unitherm satellite burner in combination with the M.A.S. rotary kiln burner. The satellite burner consists of solid secondary fuel channel and a surrounding primary air / cooling air channel. The primary air can be used together with Unitherms Pneumo-Jet or Pneumo-Deflector technology. Additionally the air prevents bending of the satellite burner.

The satellite burner is mounted on a separate trolley above the main burner and is available for both suspended and floor mounted burner trolley designs.

- Adjustment possibilities:

- Axial ±0,5 meters in burner axis

- Vertical ±2° relative to burner axis

|

|

Result plant 1

- SSF rate without satellite burner: 2,5 – 3,0 t/h

- SSF rate with satellite burner: 4,0-4,5 t/h

- SSF rate increased by: approx. 54%

|

|

Result plant 2

- SSF rate without satellite burner: 5,0-5,5 t/h

- SSF rate with satellite burner: 7,0 -7,5t/h

- SSF rate increased by: approx. 38%

The M.A.S. catalogue is available in multiple languages and can be downloaded in our download section.